Cream Dispenser

- MASDAK

2006

(Exhibited in OSAKA MOBAC SHOW 2006)

Cream squeezing machine

product development

The development process of a cream dispensers

A dispenser for non-specialists

The client wanted to develop a semi-general use cream dispenser, an easy-to-use hygienic dispenser that can be used by non- professionals for serving new types of sweets using cream at cafes or convenience stores. But with conventional dispensers the original cream package had to be opened and the cream poured into the dispensing machine, which accompanied hygiene issues that could only be handled by professionals. We proposed a system using an original pack with a valve to be attached to a corresponding cream dispenser, making it possible for non-professionals to change the pack of cream without hygienic problems. But since many pillow-packed cream products are already on the market, an original pack was a difficult alternative. The solution was a valve to be attached directly to the existing pillow packs on the market.

Cream dispenser Step1:Basic mechanism development

Basic mechanism development

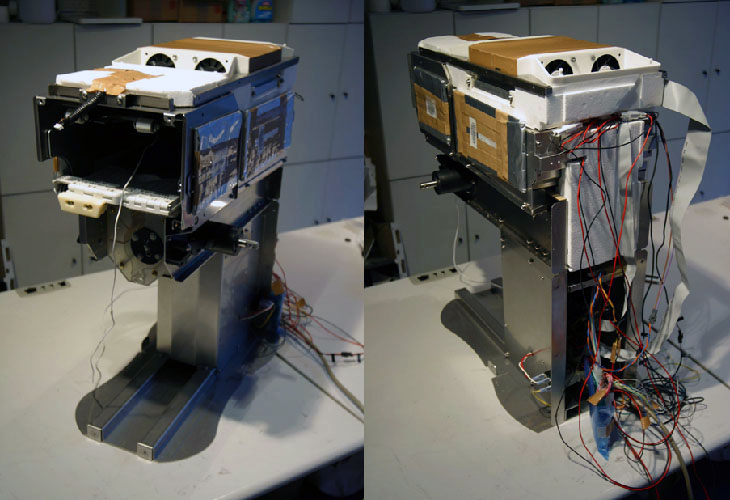

Basic structure proposal of the valve

A valve that can be attached to various pillow packs on the market was proposed.

The load capacity of a pillow pack was about 100kg, so the valve had to be able to withstand this load.

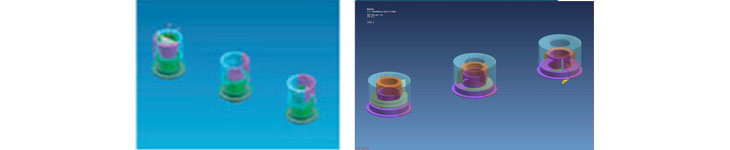

Data for the prototype was generated; working mockups were made and run through a series of tests. After six months a prototype was completed that satisfied the specified performance criteria and we proceeded to production design.

Data generation for building mass production dies

Six months after the final mockup was made, mass production design and dies were completed.

Development of a jig to attach the valve

After the valve, we developed a jig to attach it onto the pillow pack. First a simple type was made, which at the end became a computer-controlled, full-automatic type.

The lower right hand photo shows the final valve attached to a pillow pack using the jig.

Cream dispenser step 2: Development process of the dispenser body

Basic mechanism development

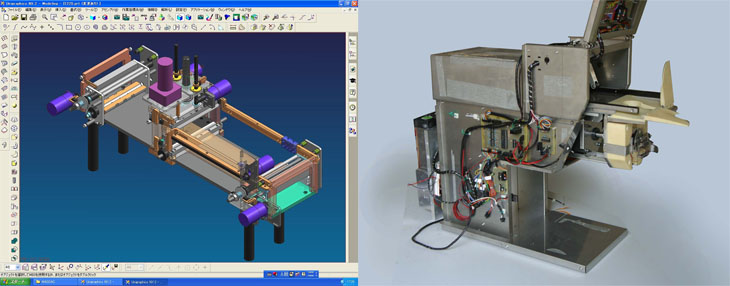

Development through 3D CAD and working prototype

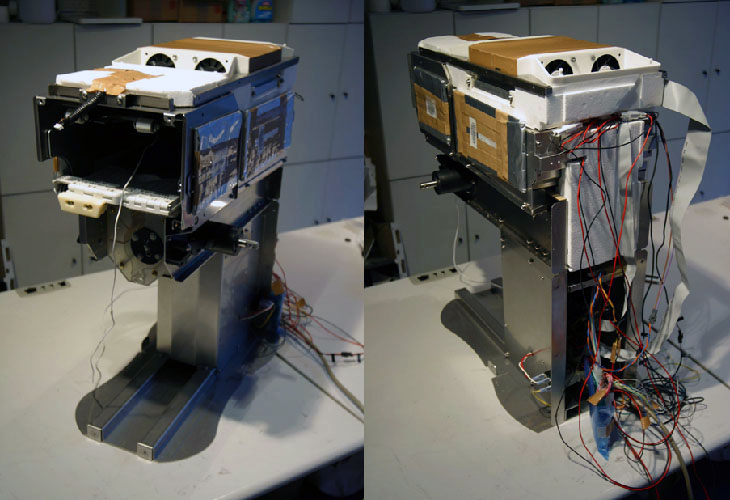

First we developed a prototype to clarify the conditions and tasks. Then we reviewed the design and made feedbacks repeatedly between the NX (3D CAD) data and the working prototype. The upper right hand photo shows the prototype in which fixed quantity squeezing was finally enabled. It is equipped with various types of sensors, uses 3 DC motors, and is controlled by a micro computer that runs an original control program.

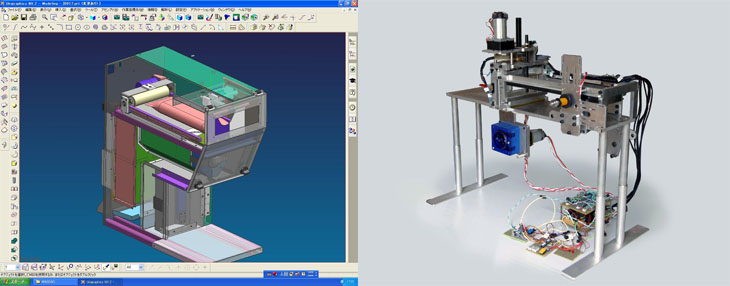

Development of the dispenser body prototype

We developed the first prototype that squeezes even when the remaining content of the pillow pack becomes 3% or less, and filed a patent for the mechanism.

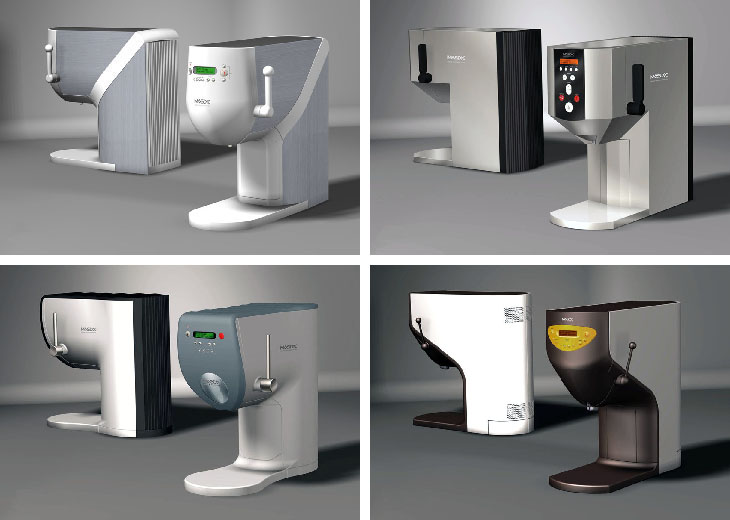

Development of design ideas

Considering the parts making up the body, design proposals were developed so as to minimize initial and running costs. The proposal with the overall advantage considering the balance between design and costs was selected to proceed to production design.

Final improvements and generation of data for die building

We solved problems discovered in the prototypes, completed mass production design, and prepared the data for die building. The final prototype was exhibited in the Osaka MOBAC Show. We assembled the model from scratch to completion on the site and made final adjustments.