disposable laparoscopic surgery forceps

- 2006

The development of a disposable laparoscopic surgery forceps

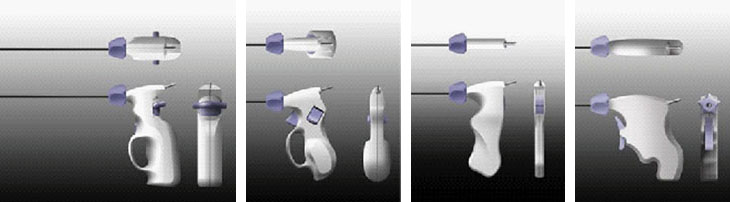

The development process of a disposable laparoscopic surgery forceps

Reconsidering the structure

proposing a new mechanism

Reconsidering the traditional structure

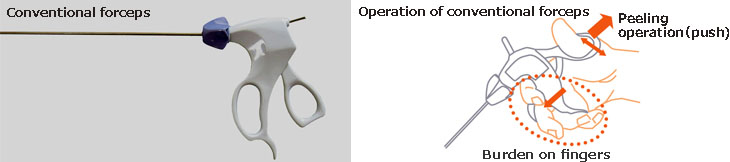

Conventional forceps require supporting of the main body and operation by the same fingers, so they tend to be unstable at the operation. Also, the separating action required the use of the backside of the thumb, which we do not normally use.

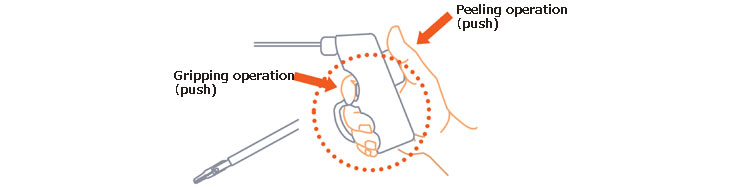

Proposing a new mechanism

In order to reduce the stress on the fingers and make operation stable, we adopted the idea to assign the roles of supporting the main body and edge operation to different fingers respectively. Furthermore, we separated the operation into holding and separation, and developed a mechanism to operate by pushing with different fingers, for which we filed a patent.

Based on the new mechanism, ideas were developed on the division of tasks between the fingers and the overall structure. Several proposals were made, and through discussions with the client, one was selected for its superiority in user-friendliness and structure.

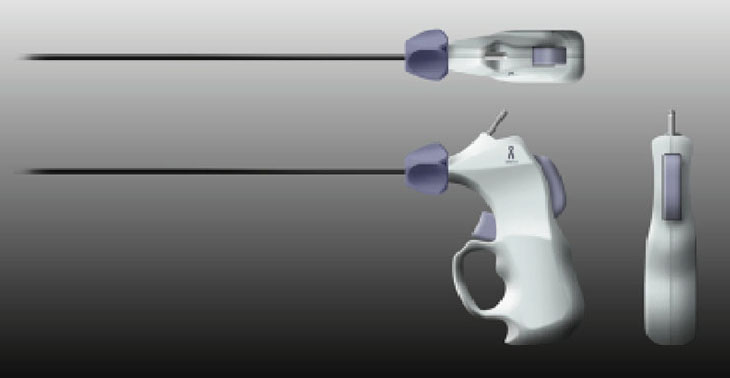

Finalization of the design

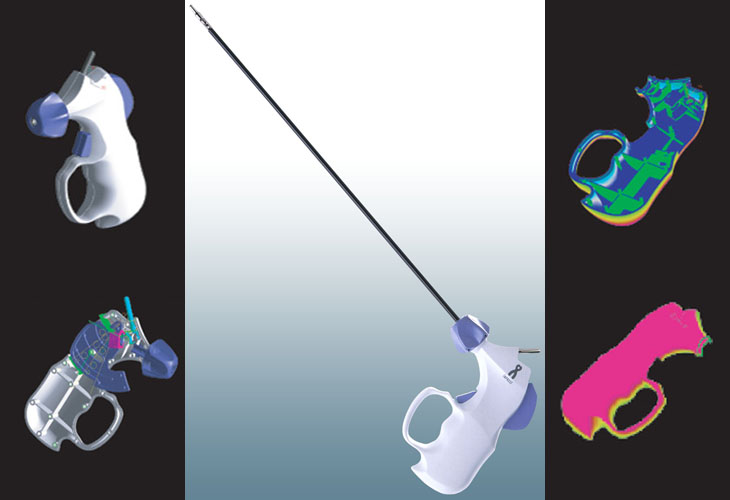

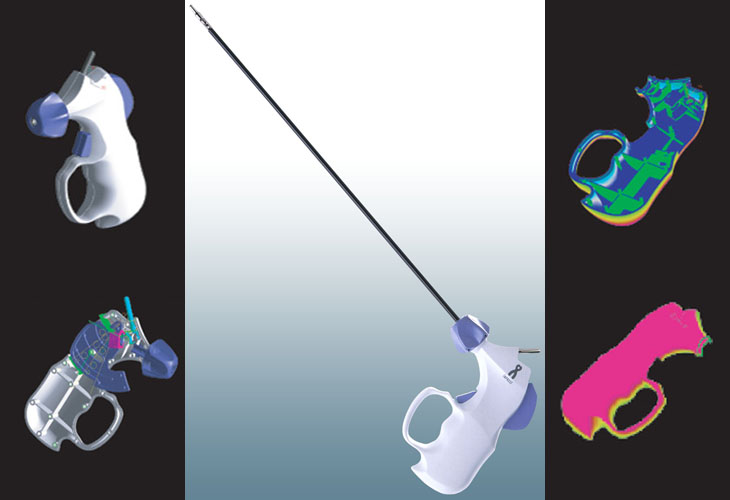

The final design was checked on 2D rendering and carried on to 3D engineering design and data generation steps.

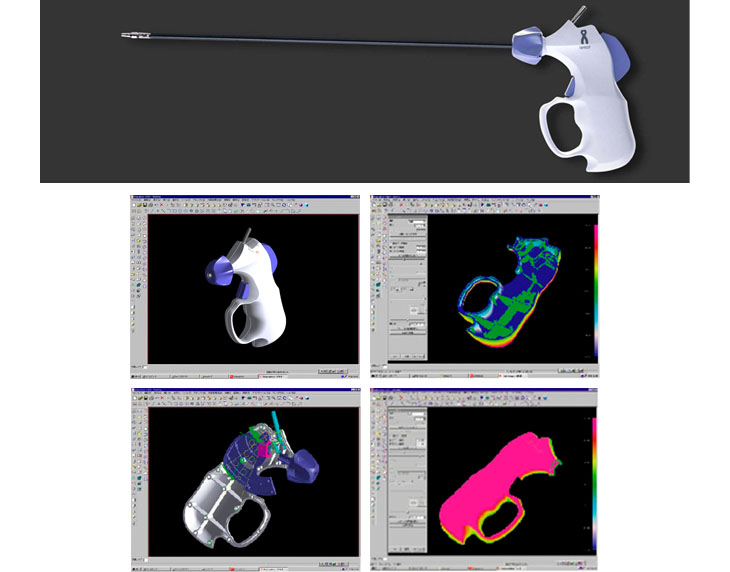

Concurrent engineering and designing

Using the NX 3D CAD application, engineering and styling design proceeded simultaneously. This allowed for consistent data handling all the way up to die building, and shortened total development time.